Категория

-

Интеллектуальное оборудование для ремонтных работ на нефтяных скважинах

-

Производственная линия лазерной резки и вырубки рулонного материала

-

Оборудование для обработки углов

-

Производственная линия JNC серии для пробивки и резки стального уголка с ЧПУ

-

Производственная линия JNC серии для пробивки, сверления и резки стального уголка с ЧПУ

-

Высокоскоростная линия производства JNCG серии для сверления и штамповки (пиления)

-

Очистительная машина для корней стальных уголков серии QG с ЧПУ

-

Машина для гибки и разгибания стальных уголков серии KH с ЧПУ и гидравлическим приводом

-

-

Интеллектуальное оборудование для производства и обработки по индивидуальному заказу

Связаться

Горячая линия продаж:

телефон: 86-186-5312-9070 (Manager Li)

Ваш email: zgjngx@163.com

Адрес: № 12, здание штаб-квартиры, город Хайнац, улица Мейли 555, район Хуайинь, город Цзинань

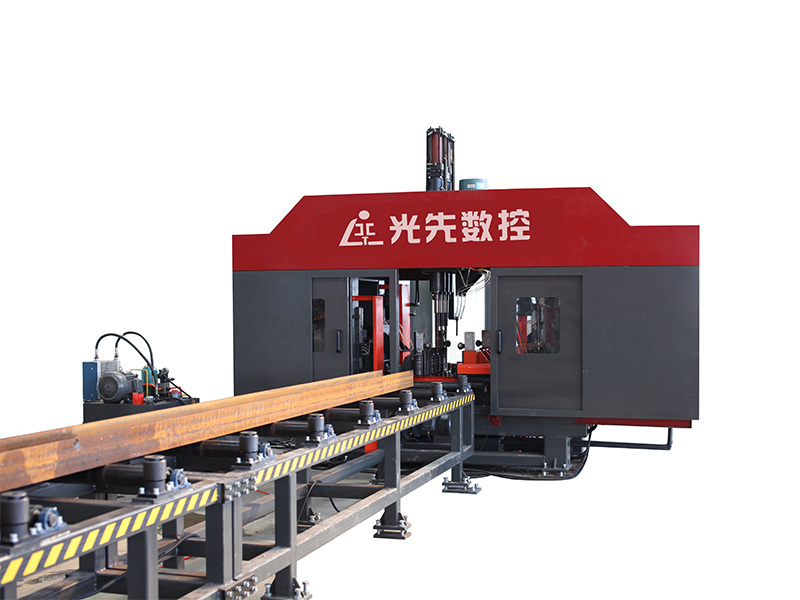

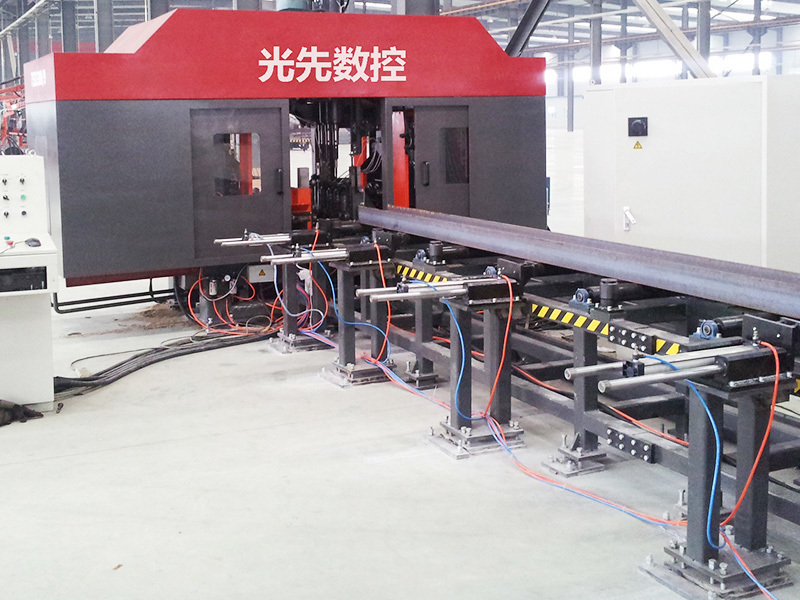

SWZ700 — трехмерный станок с ЧПУ для сверления двутавровых балок

Подробности

Трехмерный станок для сверления состоит из балки, левой и правой стоек, основания, каретки, коробки главного шпинделя, устройства для прижима сверху, устройства для бокового прижима, а также устройства для измерения толщины и ширины материала.

Станок имеет 3 коробки главного шпинделя: две боковые и одну верхнюю, для сверления в горизонтальном и вертикальном направлениях. Каждая коробка главного шпинделя может работать как отдельно, так и одновременно с другими, что значительно повышает эффективность. Каждая коробка главного шпинделя имеет 3 шпинделя с гидравлическим автоматическим ходом, на которые можно установить сверла 3-х диаметров, что позволяет обрабатывать 3 отверстия разного диаметра за одну установку заготовки. При подаче шпинделя автоматически осуществляется переключение на быструю подачу — рабочую подачу — быстрый возврат. Скорость вращения каждого шпинделя регулируется бесступенчато с помощью частотного преобразователя, а скорость подачи — бесступенчато с помощью регулирующего клапана.

Основные технические параметры:

| Название параметра |

Единица измерения |

Значение параметра |

Примечание |

||

| Заготовка |

Диапазон ширины |

мм |

100~500 |

|

|

| Диапазон высоты |

мм |

100~500 |

|

||

| Минимальная длина автоматической подачи |

мм |

2000 |

|

||

| Максимальная длина заготовки |

мм |

12000 |

|

||

| Шпиндель |

Количество шпинделей |

шт. |

9 |

|

|

| Мощность электродвигателя шпинделя |

кВт |

Около 5,5 |

|

||

| Диапазон скорости вращения каждого шпинделя |

об/мин |

180~560 |

|

||

| Диапазон диаметров сверления |

мм |

φ12~φ30 |

|

||

| Число |

Ось X |

Мощность серводвигателя |

кВт |

Около 4,5 |

|

| Максимальная скорость |

м/мин |

40 |

|

||

| Ось Y |

Мощность серводвигателя |

кВт |

Около 1,5 |

|

|

| Максимальная скорость |

м/мин |

10 |

|

||

| Оси Z, W |

Мощность серводвигателя |

кВт |

Около 1,5 |

|

|

| Максимальная скорость |

м/мин |

10 |

|

||

Оставить заявку

Пожалуйста, заполните вашу контактную информацию и ваши потребности, и мы организуем профессионала, чтобы связаться с вами!