Категория

-

Интеллектуальное оборудование для ремонтных работ на нефтяных скважинах

-

Производственная линия лазерной резки и вырубки рулонного материала

-

Оборудование для обработки углов

-

Производственная линия JNC серии для пробивки и резки стального уголка с ЧПУ

-

Производственная линия JNC серии для пробивки, сверления и резки стального уголка с ЧПУ

-

Высокоскоростная линия производства JNCG серии для сверления и штамповки (пиления)

-

Очистительная машина для корней стальных уголков серии QG с ЧПУ

-

Машина для гибки и разгибания стальных уголков серии KH с ЧПУ и гидравлическим приводом

-

-

Интеллектуальное оборудование для производства и обработки по индивидуальному заказу

Связаться

Горячая линия продаж:

телефон: 86-186-5312-9070 (Manager Li)

Ваш email: zgjngx@163.com

Адрес: № 12, здание штаб-квартиры, город Хайнац, улица Мейли 555, район Хуайинь, город Цзинань

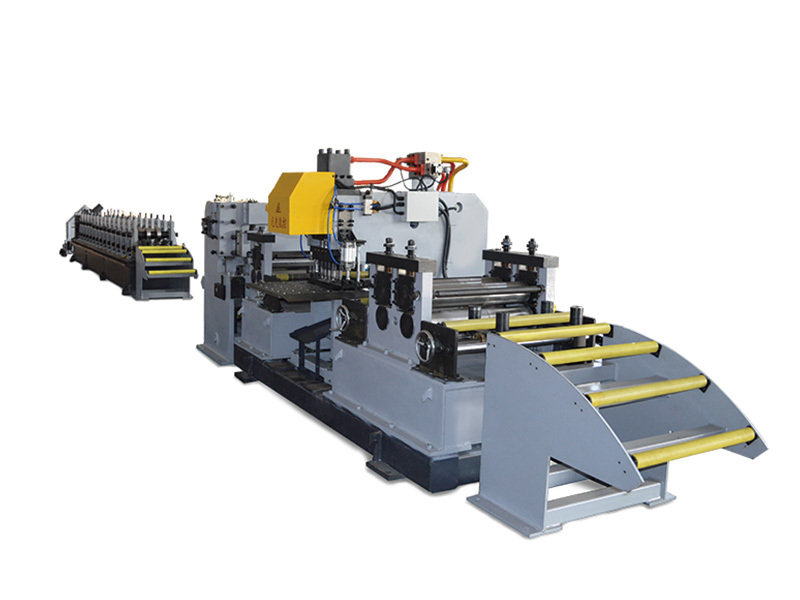

Производственная линия для пробивки и роликовой прокатки с ЧПУ модели SBL500

Ключевые слова:

Подробности

Производственная линия для пробивки и роликовой прокатки с ЧПУ модели SBL500 в основном используется для производства необходимых плоских балок для автомобилей из рулонной стали путем размотки, выравнивания, пробивки с ЧПУ, плазменной резки и других операций. Это повышает точность обработки, производительность, снижает себестоимость и повышает безопасность производства.

Производственная линия состоит из тележки для загрузки, разматывающего устройства, выпрямителя, буферного устройства, устройства для пробивки с ЧПУ (включая устройство для плазменной резки), роликового конвейера для выгрузки, гидравлической системы, пневматической системы и электрической системы.

Система управления данного станка состоит из хост-компьютера и ПЛК. Способы программирования: ввод с клавиатуры, ввод через USB-интерфейс, создание программы обработки с помощью CAD. Программы обработки можно хранить, вызывать, отображать и передавать по номеру детали в любое время. Станок может осуществлять как индивидуальную ручную регулировку параметров обработки, так и автоматическую обработку всего процесса.

Основные технические параметры производственной линии

| Название параметра |

Единица измерения |

Значение параметра |

Примечания |

|

| Параметры материала |

Ширина рулона |

мм |

360~500 |

|

| Толщина материала |

мм |

4 |

Отклонение ширины листа составляет ±0,5 мм. Прямолинейность 0,5 мм/м |

|

| Внутренний диаметр рулона |

мм |

φ508 ~φ610 |

|

|

| Внутренний диаметр рулона |

мм |

φ1600 |

|

|

| Вес рулона |

т |

6 |

|

|

| Параметры заготовки |

Материал заготовки |

|

Q235A |

|

| Длина готового изделия |

мм |

2500~5200 |

|

|

| Максимальный диаметр отверстия |

мм |

φ30 |

|

|

| Минимальный диаметр отверстия |

мм |

больше или равно толщине листа |

|

|

| Допуск на размер расстояния между отверстиями |

мм |

±0,5 |

|

|

| Допуск по длине |

мм |

±2 |

|

|

| Параметры блока ЧПУ для пробивки и резки |

Мощность серводвигателя оси X |

кВт |

3 |

|

| Максимальная скорость перемещения оси X |

м/мин |

15 |

|

|

| Мощность серводвигателя оси Y |

кВт |

4.5 |

|

|

| Максимальная скорость перемещения оси Y |

м/мин |

20 |

|

|

| Количество позиций |

шт |

7 |

|

|

| Источник питания плазмы |

шт |

1 |

American Hypertherm |

|

| Параметры блока размотки и выравнивания |

Внешний диаметр выравнивающих валков |

мм |

120 |

|

| Материал выравнивающих валков |

|

GGr15 |

|

|

| Мощность двигателя выравнивания |

кВт |

5.5 |

|

|

| Параметры гидравлической системы |

Рабочее давление высоковольтного контура |

МПа |

24 |

|

| Рабочее давление низковольтного контура |

МПа |

6 |

|

|

| Габариты производственной линии |

мм |

приблизительно 23000×5500×2500 |

|

|

Оставить заявку

Пожалуйста, заполните вашу контактную информацию и ваши потребности, и мы организуем профессионала, чтобы связаться с вами!