Категория

-

Интеллектуальное оборудование для ремонтных работ на нефтяных скважинах

-

Производственная линия лазерной резки и вырубки рулонного материала

-

Оборудование для обработки углов

-

Производственная линия JNC серии для пробивки и резки стального уголка с ЧПУ

-

Производственная линия JNC серии для пробивки, сверления и резки стального уголка с ЧПУ

-

Высокоскоростная линия производства JNCG серии для сверления и штамповки (пиления)

-

Очистительная машина для корней стальных уголков серии QG с ЧПУ

-

Машина для гибки и разгибания стальных уголков серии KH с ЧПУ и гидравлическим приводом

-

-

Интеллектуальное оборудование для производства и обработки по индивидуальному заказу

Связаться

Горячая линия продаж:

телефон: 86-186-5312-9070 (Manager Li)

Ваш email: zgjngx@163.com

Адрес: № 12, здание штаб-квартиры, город Хайнац, улица Мейли 555, район Хуайинь, город Цзинань

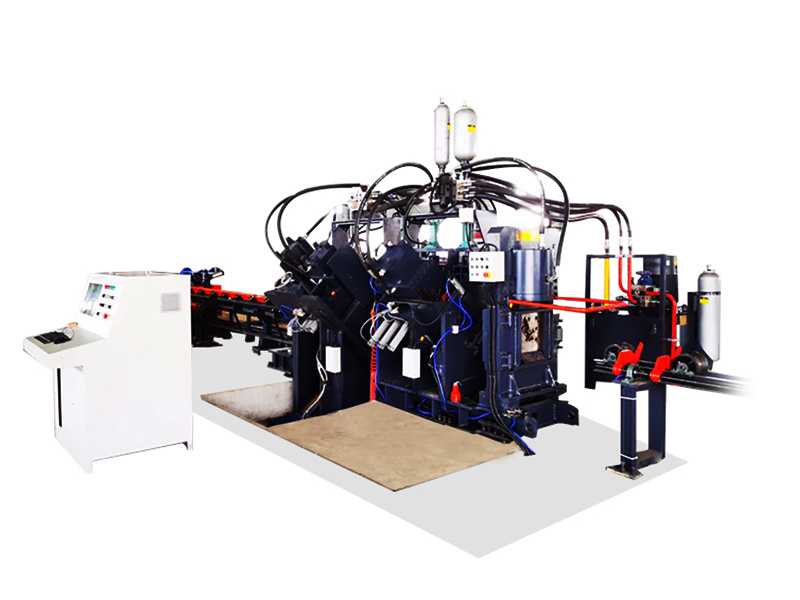

Линия по производству штамповки, пробивки и резки балок и уголков с ЧПУ модели CJNC1614

Подробности

I. Назначение и особенности производственной линии

1. Данная производственная линия предназначена для трехсторонней числовой обработки швеллеров с помощью маркировки, пробивки и резки, характеризуется высокой точностью обработки, высокой скоростью пробивки и высокой производительностью.

2. Подходит как для массового производства швеллеров, так и для мелкосерийного производства новых продуктов с большим разнообразием.

3. Данная производственная линия предназначена для числовой обработки уголков с помощью маркировки, пробивки и резки, характеризуется высокой точностью обработки, высокой скоростью пробивки и высокой производительностью.

Технологические параметры заготовок:

1. Данные швеллера до обработки:

1.1 Материал заготовки: Q355

1.2 Длина заготовки швеллера: 6000~9000 мм

1.3 Максимальная длина готового швеллера: 9000 мм

1.4 Номиналы швеллеров, которые можно обрабатывать: №8~№16

1.5 Отклонения размеров и формы швеллера соответствуют требованиям государственного стандарта GB/T706-2016.

2. Данные швеллера после обработки:

2.1 Номиналы диаметров отверстий в швеллере:

Максимальный диаметр отверстия на полке: Φ26 мм, толщина материала ≤12 мм

Минимальный диаметр отверстия на полке: ≥ толщины полки

Максимальный диаметр отверстия на стенке: Φ26 мм, толщина материала ≤12 мм

Минимальный диаметр отверстия на стенке: ≥ максимальной толщины стенки в месте пробивки отверстия.

2.2 Погрешность расстояния между отверстиями: ±0,7 мм

Оставить заявку

Пожалуйста, заполните вашу контактную информацию и ваши потребности, и мы организуем профессионала, чтобы связаться с вами!