Категория

-

Интеллектуальное оборудование для ремонтных работ на нефтяных скважинах

-

Производственная линия лазерной резки и вырубки рулонного материала

-

Оборудование для обработки углов

-

Производственная линия JNC серии для пробивки и резки стального уголка с ЧПУ

-

Производственная линия JNC серии для пробивки, сверления и резки стального уголка с ЧПУ

-

Высокоскоростная линия производства JNCG серии для сверления и штамповки (пиления)

-

Очистительная машина для корней стальных уголков серии QG с ЧПУ

-

Машина для гибки и разгибания стальных уголков серии KH с ЧПУ и гидравлическим приводом

-

-

Интеллектуальное оборудование для производства и обработки по индивидуальному заказу

Связаться

Горячая линия продаж:

телефон: 86-186-5312-9070 (Manager Li)

Ваш email: zgjngx@163.com

Адрес: № 12, здание штаб-квартиры, город Хайнац, улица Мейли 555, район Хуайинь, город Цзинань

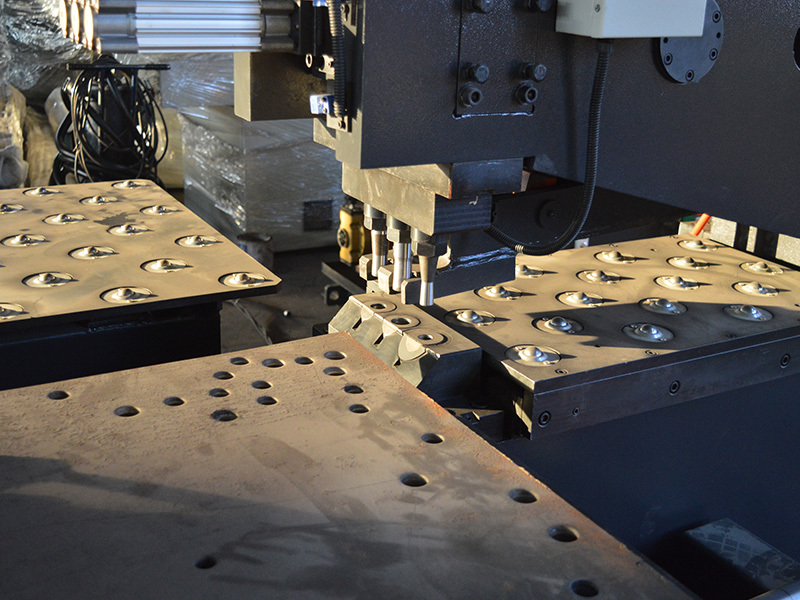

Станок для пробивки (сверления) отверстий и маркировки на печатных платах с ЧПУ типа BNCZ100

Подробности

Автомат для пробивки и маркировки соединительных плат типа BNC100 с ЧПУ

На данный продукт получены несколько национальных патентов, номера которых: 2015 2 1014818.5 2015 2 0948896.6 2013 2 0434794.3 и др.

Данный станок предназначен для пробивки отверстий и маркировки металлических листов, это специализированное устройство с ЧПУ для полностью автоматизированного производства.

Корпус станка представляет собой сварную конструкцию из профильной стали С-образного сечения, отличается высокой жесткостью и большим рабочим пространством. Станок имеет три позиции для оснастки (одна из которых предназначена для маркировки), переключение позиций осуществляется автоматически. Система зажимов подходит для заготовок различной толщины, оснащена упором для базовой нулевой точки, заготовка опирается на шариковый стол. Перемещение по осям X и Y осуществляется с помощью серводвигателей и шарико-винтовых пар, положение пробивки контролируется двухкоординатной системой ЧПУ, весь процесс обработки выполняется автоматически. Оператор вводит размеры заготовки в компьютер, после чего их можно использовать повторно.

Использование технологии ЧПУ, серводвигателя для подачи, высокая эффективность, стабильная точность обработки заготовок

Длинные направляющие для ползуна пробивки увеличивают срок службы пуансона и матрицы

На одной и той же плате можно выполнять пробивку, маркировку и сверление.

Сверлильный блок имеет функции быстрого хода вхолостую, медленного рабочего хода и быстрого возврата, что повышает эффективность работы.

Простое программирование: можно ввести диаметр отверстия, положение, количество заготовок, а также использовать программы, созданные в программном обеспечении для раскроя, или использовать прямую конвертацию из CAD/CAM.

Функция самодиагностики неисправностей.

| Модель станка |

BNCZ100 |

||

| Максимальный размер заготовки (мм) |

1500×800 |

||

|

Максимальная пробивная способность (мм) |

φ26×25(материал Q345 510Н/мм²) |

||

| Толщина листа для пробивки (мм) |

5~25 |

||

| Максимальный диаметр сверления (мм) |

50 |

||

| Максимальная толщина листа для сверления (мм) |

40 |

||

|

Усилие пробивки (кН) |

1000 |

||

| Усилие маркировки (кН) |

800 |

||

| Минимальное расстояние от отверстия до края листа (мм) |

Зависит от диаметра отверстия |

||

|

Размер символов (мм) |

14×10×19 (в зависимости от требований заказчика)

|

||

| Количество символов |

12 |

||

| Количество позиций для оснастки |

4 |

||

| Точность обработки |

Соответствует требованиям GB2694 |

||

| Режим программирования |

Ввод с клавиатуры, ввод через USB-интерфейс, преобразование из CAD |

||

| Габаритные размеры (мм) |

3200×3000×1900 |

||

Оставить заявку

Пожалуйста, заполните вашу контактную информацию и ваши потребности, и мы организуем профессионала, чтобы связаться с вами!